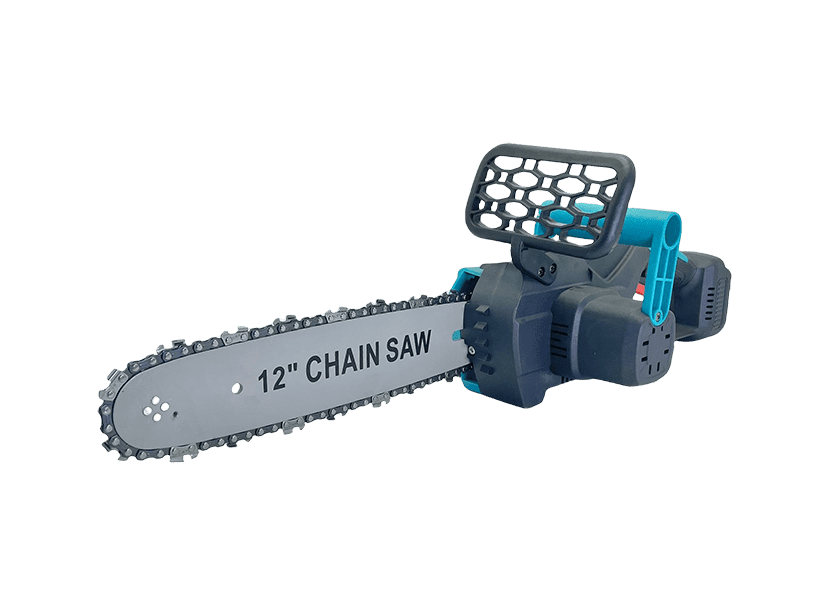

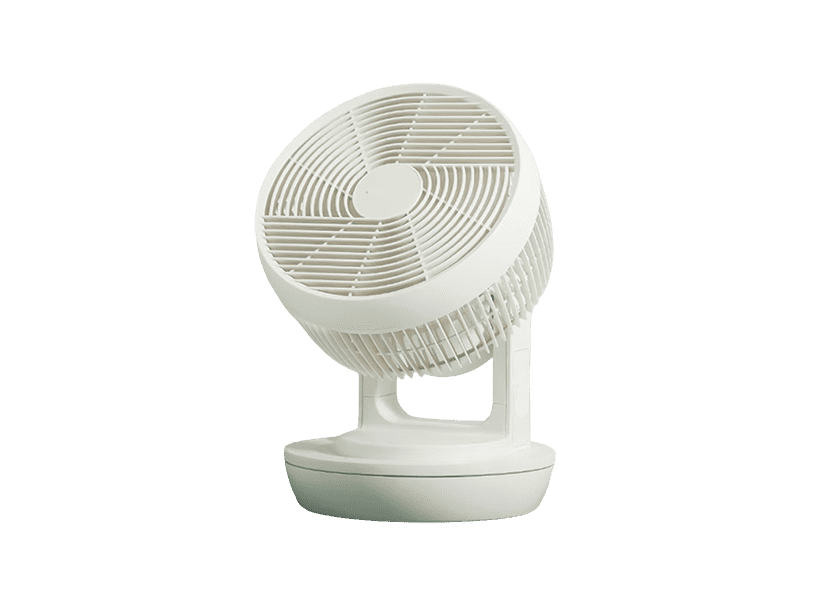

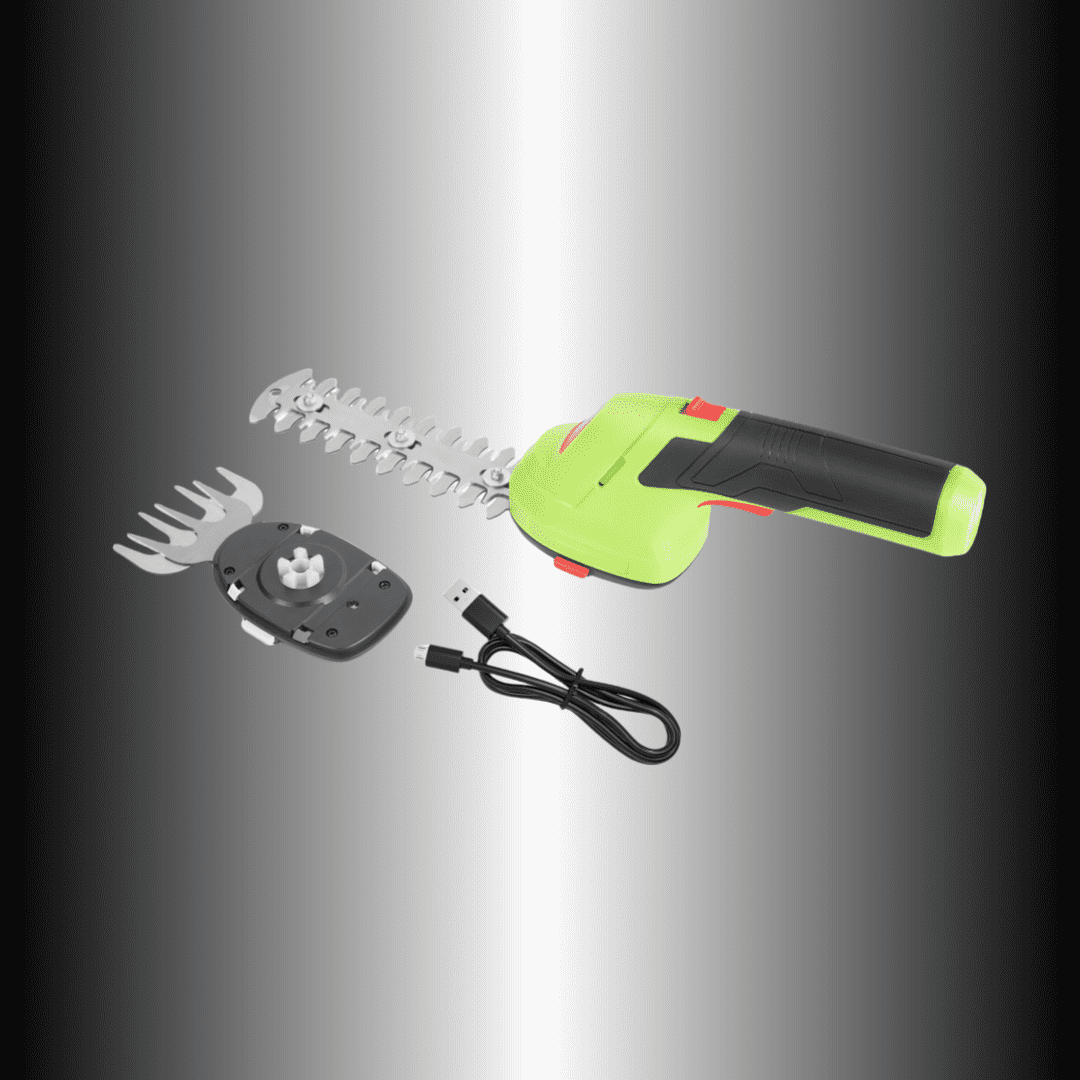

Key Product Information

01

Efficiency

02

The Secret of the Product

03

The Difference Between Brushless and Brushed Motors

FeatureBrushed MotorsBrushless Motors

Efficiency 75-80% (energy loss from friction/sparks) 85-90% (no brush friction)

Lifespan 500-1,000 hrs (brush wear) 10,000+ hrs (no wear parts)

Maintenance Regular brush replacement Virtually maintenance-free

Speed Control Limited by mechanical commutation Precise, high-speed response

Cost Lower initial cost Higher (requires ESC)

3. Key Advantages

Brushed: Simple, cost-effective for low-duty applications (e.g., toys, basic tools).

Brushless: Higher power density, longer lifespan, ideal for drones, EVs, and premium power tools.

4. Real-World Impact

A brushless motor in a drone increases flight time by 20-30% versus brushed.

Industrial brushless systems reduce downtime by 90% due to no brush wear.

(Translation Notes:

Technical terms like “ESC” (Electronic Speed Controller) retained for accuracy.

Tabular format enhances technical comparison clarity.

Bolded key specs highlight critical differences.

Real-world data (e.g., “20-30%”) added to reinforce practical implications.)

04

About Battery Packs

Differences Between 5C and 10C Power Batteries

1. Discharge Capacity

- 5C Battery: Maximum continuous discharge current = 5× rated capacity

(e.g., A 1000mAh battery can deliver 5A sustained current)

- 10C Battery: Maximum continuous discharge current = 10× rated capacity

(e.g., A 1000mAh battery can deliver 10A sustained current)

2. Typical Applications

Parameter | 5C Battery | 10C Battery |

Common Uses | E-bikes / Low-speed EVs | Racing drones / High-performance RC models |

Runtime | Long-duration (>30 mins) | Short bursts (<15 mins) |

Voltage System | Medium-low voltage (48-72V) | High voltage (>100V) |

3. Key Technical Differences

- Internal Resistance: 10C batteries have ~40% lower resistance

- Cooling Requirements: 10C needs 30% more heat dissipation

- Cycle Life: 5C typically lasts 200+ more cycles

- Cost: 10C batteries are 25-35% more expensive

Selection Guide

✓ Choose 5C When You Need:

- Cost-effective solutions

- Longer cycle life

- Moderate sustained power output

✓ Choose 10C When You Need:

- Instant high-power bursts (e.g., acceleration/takeoff)

- Strict weight limitations

- Frequent charge/discharge cycles

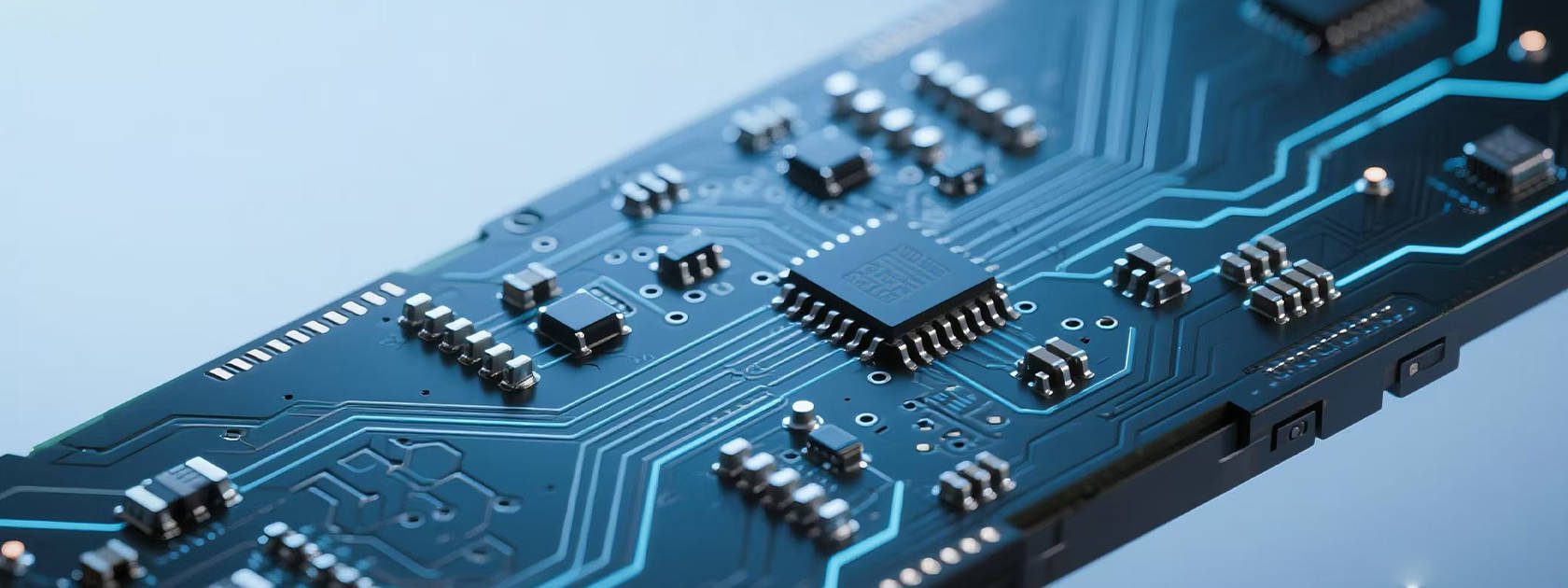

05

Circuit Control Board

We typically use standard general-purpose circuit control PCBs.

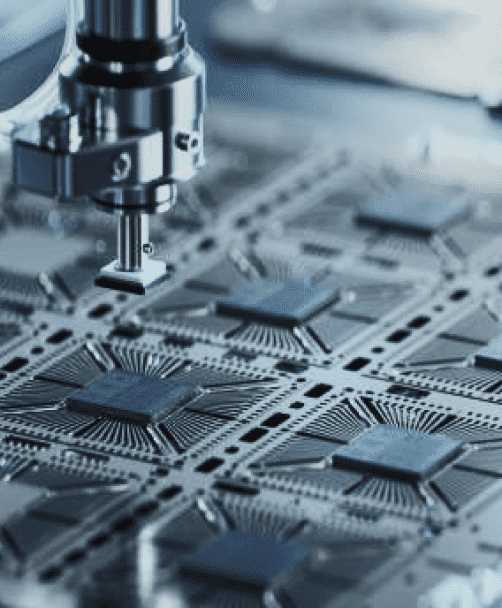

About Us

Own production machines, injection molding machines, punching

machines, and automated equipment

Own production lines, stable shipments

Can customize products to meet needs

Affordable prices, product quality can be controlled

Ningbo Jinju International Trade Co., Ltd. is a company that serves international customers, and Ningbo Fenghua Jinju Crafts Co., Ltd. is a factory that produces our products.

The factory was established in 2014 and has its own production line to manufacture products. It is located in Ningbo, Zhejiang Province, with a site area of 1,500 square meters and dozens of employees.

Win-Win Cooperation

Personalized Product Customization & R&D

Focusing on customer and market demands, we deliver targeted product development solutions with high efficiency and quality. Confidentiality agreements are available upon request.

Customized Order Collaboration

We accommodate both small-batch and large-volume customized orders. Typically, mold fees are required for small-batch orders due to high tooling costs. However, these fees can be waived when the order quantity reaches a certain threshold (the exact quantity required for mold fee exemption depends on the structure and weight of the customized product).

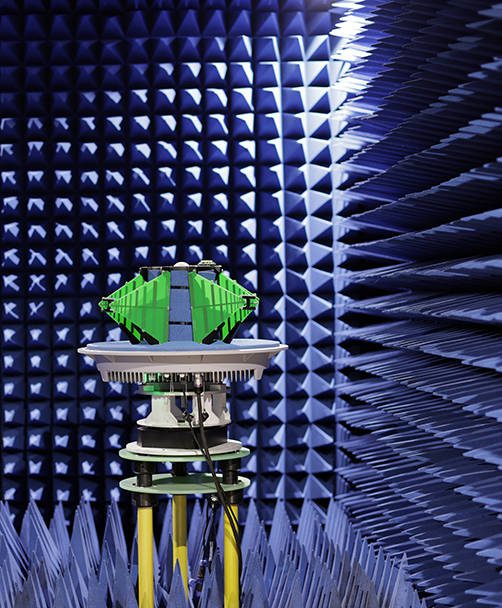

Advanced R&D Center

Focuses on analyzing customer and marketdemands. Leading strategic R&D departmentcontributed to advanced outcomes.